Lockout stations play a crucial role in industrial safety. They ensure that workers properly shut off hazardous equipment and prevent accidental startups until maintenance or repair work is complete. These stations form an essential part of the Lockout/Tagout (LOTO) procedures, designed to protect workers from the unexpected release of hazardous energy. In this article, we’ll explore the various aspects of lockout stations, including their components, types, benefits, and best practices for implementation and maintenance.

Understanding Lockout/Tagout (LOTO)

Lockout/Tagout is a safety procedure that ensures workers shut off dangerous machines properly and prevent them from starting up again before maintenance or repair work finishes. According to OSHA (Occupational Safety and Health Administration), LOTO standards are crucial in preventing accidental machine startups, which can cause serious injuries or fatalities. The key components of LOTO procedures include locks, tags, and devices that isolate energy sources.

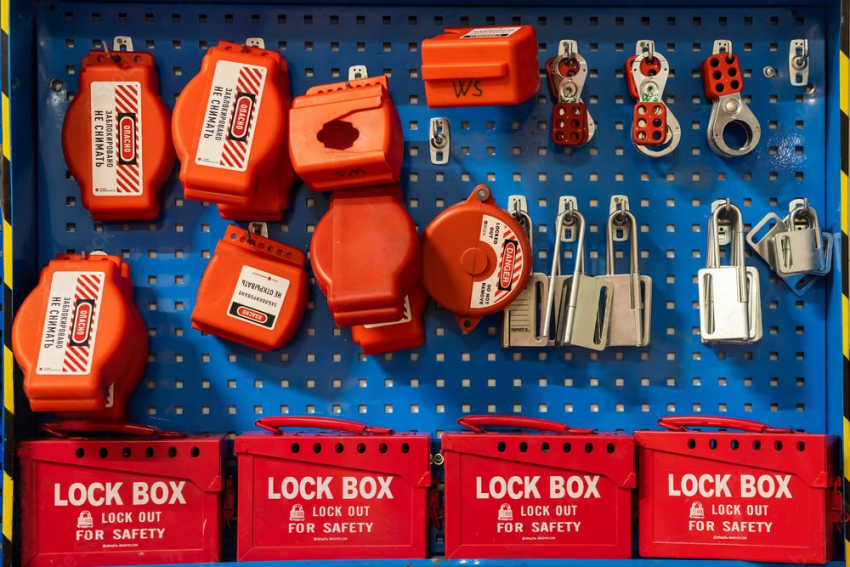

Components of a Lockout Station

A lockout station typically consists of several essential items designed to secure hazardous energy sources. These components include:

- Locks and Tags: Workers use these to secure and label the energy isolation points.

- Lockout Devices: These physically prevent the activation of equipment.

- Lockout Hasps: These allow multiple workers to apply their locks to a single energy isolation point.

- Safety Padlocks: Specifically designed for LOTO procedures, these padlocks are often color-coded.

- Key Cabinets: These provide secure storage solutions for keys and lockout devices.

Types of Lockout Stations

Lockout stations come in various types to suit different workplace needs. For example:

- Wall-Mounted Lockout Stations: These stations remain fixed in one location, making them ideal for workplaces with consistent maintenance areas.

- Portable Lockout Stations: These stations offer flexibility in larger facilities because workers can move them as needed.

- Group Lockout Boxes: These boxes allow multiple workers to lock out a single piece of equipment.

- Modular Lockout Stations: These stations are customizable to fit specific requirements and can be expanded as needed.

Selecting the Right Lockout Station

Choosing the appropriate lockout station involves assessing workplace needs, considering capacity and storage requirements, and ensuring the station’s durability. Furthermore, it’s crucial to ensure compliance with relevant safety standards to provide a safe working environment.

Benefits of Using Lockout Stations

Implementing lockout stations provides numerous benefits. They enhance workplace safety by preventing accidental equipment startups. Moreover, they improve compliance and accountability, streamline LOTO procedures, and significantly reduce the risk of accidents and injuries.

Implementing Lockout Stations in Your Facility

To effectively implement lockout stations, start with a safety audit to identify potential hazards. Train employees on proper LOTO procedures, establish a maintenance schedule, and conduct regular inspections and audits to ensure ongoing compliance and effectiveness.

Best Practices for Maintaining Lockout Stations

Regular maintenance of lockout stations is essential. Conduct inventory checks to ensure all devices are accounted for, update lockout devices as needed, ensure tags remain readable, and replace any damaged equipment immediately to maintain safety standards.

Case Studies: Successful Implementation of Lockout Stations

Implementing lockout stations has led to success in various industries. For instance:

- Manufacturing Plant: Improved safety records and reduced downtime by implementing wall-mounted lockout stations.

- Chemical Processing Facility: Enhanced compliance with stringent safety regulations through the use of portable lockout stations.

- Food and Beverage Industry: Streamlined LOTO procedures and improved employee training programs with group lockout boxes.

Common Challenges and Solutions

Implementing lockout stations can present several challenges. Resistance to change, ensuring consistent use, dealing with lost or damaged locks, and integrating with existing safety protocols are common issues. However, solutions involve continuous employee education, maintaining an inventory system, and incorporating lockout stations into the broader safety management framework.

Technological Advances in Lockout Stations

Advancements in technology have led to the development of digital lockout systems, RFID and barcode integration, smart lockout devices, and mobile applications for managing LOTO procedures. Consequently, these innovations enhance the efficiency and effectiveness of lockout stations.

Regulatory Compliance and Legal Considerations

Compliance with OSHA requirements is mandatory. Proper documentation and record-keeping are crucial for demonstrating compliance and avoiding legal issues. Regular reviews and updates of LOTO procedures help ensure ongoing adherence to safety regulations.

Training and Education for Effective LOTO Implementation

Effective LOTO implementation requires comprehensive training programs. These should include hands-on training, workshops, and regular evaluations to ensure that employees understand and adhere to safety protocols. Supervisors and safety officers play a key role in reinforcing these practices.

Conclusion

Lockout stations are vital for maintaining a safe work environment and ensuring compliance with safety regulations. By implementing and maintaining effective LOTO systems, organizations can protect their employees, reduce the risk of accidents, and enhance overall workplace safety.

FAQs

- What is the primary purpose of a lockout station? The primary purpose of a lockout station is to provide a centralized location for storing and managing lockout/tagout devices. This ensures that workers properly isolate hazardous energy sources during maintenance and repair work.

- How often should lockout stations be inspected? Inspect lockout stations regularly, at least once a month, to ensure all components remain in good condition and properly accounted for.

- Can lockout stations be customized? Yes, you can customize lockout stations to meet the specific needs of a facility, including the type and number of lockout devices required.

- What training is required for employees to use lockout stations? Employees should receive comprehensive training on LOTO procedures. This training should include the proper use of lockout stations, device application, and safety protocols.

- Are there any technological tools to help manage lockout stations? Yes, various technological tools are available. These include digital lockout systems, RFID and barcode integration, smart lockout devices, and mobile applications that help manage and streamline LOTO procedures.