In any industrial or manufacturing setting, safety is paramount. Implementing proper lockout tagout procedures is crucial to safeguarding employees and preventing workplace accidents.

What Are Lockout Tagout Boxes?

Lockout Tagout (LOTO) boxes are essential tools used in industrial and manufacturing settings to ensure the safety of workers during maintenance and repair activities. These boxes serve as a centralized point for securing keys to locked-out equipment, ensuring that machinery cannot be activated accidentally while maintenance is being performed. LOTO boxes are designed to hold multiple keys from various lockout points, providing a systematic approach to controlling hazardous energy. They are an integral part of the lockout tagout procedure, which aims to prevent accidental start-up of equipment and protect workers from injuries caused by unexpected energy release.

Importance of Using Lockout Tagout Boxes

The use of lockout tagout boxes is critical for compliance with occupational safety regulations and for fostering a safe working environment. By employing these boxes, companies can ensure that only authorized personnel have access to keys, thus preventing unauthorized or accidental re-energization of equipment. This centralized system helps in maintaining strict control over who can remove locks or tags and ensures that all maintenance personnel are aware of the lockout status. In essence, LOTO boxes contribute to reducing workplace accidents and enhancing the overall safety culture within an organization.

Types of Lockout Tagout Boxes

Lockout tagout boxes come in various designs and sizes to accommodate different workplace needs. Portable LOTO boxes are ideal for smaller facilities or for maintenance teams that need to move from one location to another. They are lightweight and easy to carry, providing flexibility and convenience. Wall-mounted LOTO boxes, on the other hand, offer a fixed, secure location for storing lockout keys, making them suitable for larger facilities with dedicated maintenance areas. Additionally, there are group lockout boxes designed to hold multiple locks and keys, allowing for collective lockout procedures where several workers need to lock out the same piece of equipment.

How to Properly Use Lockout Tagout Boxes

Proper usage of lockout tagout boxes involves several key steps to ensure maximum safety. First, identify all energy sources that need to be locked out and isolate them using appropriate lockout devices. Place the keys to these lockout devices in the LOTO box and secure the box with a lock. Each maintenance worker then applies their personal lock to the LOTO box, ensuring that the equipment cannot be re-energized until all locks are removed. This system ensures that maintenance activities cannot proceed until every worker involved has confirmed that it is safe to do so, thereby preventing accidental injuries.

Benefits of Implementing Lockout Tagout Boxes

Implementing lockout tagout boxes in a workplace offers numerous benefits beyond compliance with safety regulations. These boxes enhance communication among maintenance teams by providing a clear visual indication of equipment status. They also streamline the lockout process, making it easier to manage and track lockout activities. Moreover, LOTO boxes help in maintaining a detailed record of lockout events, which can be valuable for audits and continuous improvement efforts. Ultimately, the use of lockout tagout boxes leads to a safer working environment, reducing the risk of accidents and ensuring the well-being of all employees involved in maintenance tasks.

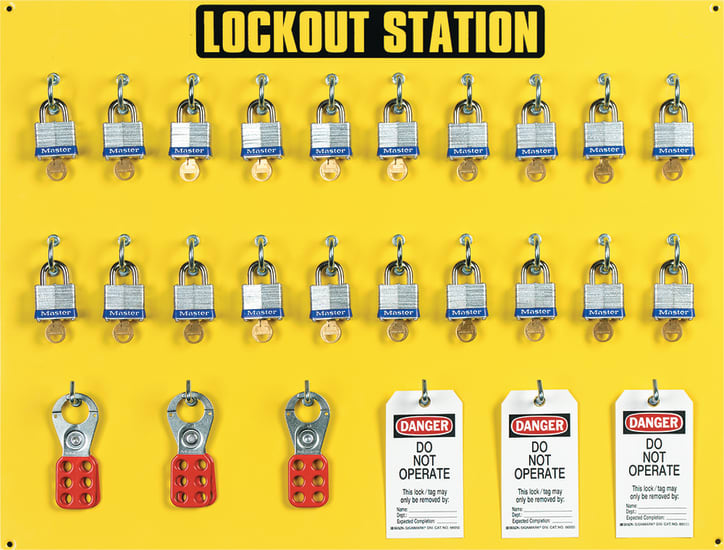

Understanding the Lockout Tagout Station

At the heart of these procedures lies the lockout tagout station. This station serves as a centralized hub where employees can access the necessary equipment and information to safely isolate machinery or equipment from its energy sources during maintenance or servicing. From lockout devices to tags, padlocks, and comprehensive instructions, the station provides everything needed to ensure effective lockout tagout procedures.

Why Lockout Tagout is Vital

The primary purpose of a lockout tagout is to prevent the unexpected startup or release of hazardous energy while maintenance or repairs are being performed. By effectively isolating energy sources and clearly communicating the status of equipment through tags and locks, workers are protected from potentially life-threatening accidents. These accidents can result in serious injuries or even fatalities, making the proper implementation of lockout tagout procedures essential in any industrial or manufacturing environment.

Streamlining Procedures with a Dedicated Station

One of the key benefits of a well-equipped lockout tagout station is its ability to streamline the lockout tagout process. With all the necessary tools and instructions readily available in one location, workers can efficiently carry out lockout tagout procedures without delay or confusion. This not only saves valuable time but also ensures consistency across operations, reducing the risk of errors or oversights that could compromise safety.

Meeting Compliance Standards

Moreover, a properly implemented lockout tagout program, supported by a dedicated station, demonstrates a commitment to compliance with relevant regulatory standards. Employers have a legal and moral obligation to provide a safe working environment for their employees, and investing in robust lockout tagout procedures is a crucial step in fulfilling that responsibility. By adhering to regulatory requirements and best practices in lockout tagout, organizations can mitigate risks, avoid penalties, and protect both their employees and their bottom line.

Conclusion: Prioritizing Safety

In conclusion, a lockout tagout station is not just a piece of equipment; it’s a cornerstone of workplace safety. By establishing comprehensive lockout tagout procedures and equipping employees with the necessary resources, organizations can prevent accidents, protect their workforce, and promote a culture of safety. Remember, when it comes to safety, there’s no room for compromise.